The Modern Cooperage Barrel

Modern Cooperage began with the idea that wine maturation and storage was long overdue for significant disruption.

Barrels have remained nearly identical in their form for centuries, and while quality and consistency in wooden cooperage have increased, the nature of using wood exclusively for quality wine storage and maturation remains fundamentally antiquated.

So much of the wine world has changed and updated, and Modern Cooperage brings wine maturation fully into the 21st century, with significant quality-of-life improvements for winemakers, positive ecological impact for the planet, and significant cost savings on material and labor, all without compromising on any of the quality that makes wines matured in traditional cooperage so magical.

2010

2011

Taking learnings from the first generation certain design modifications were made for effective methods for oak flavor extraction.

2013

2015

A passive oxygen permeable membrane designed to allow the slow controlled transfer of oxygen to facilitate the polymerization of phenolic compounds.

Present

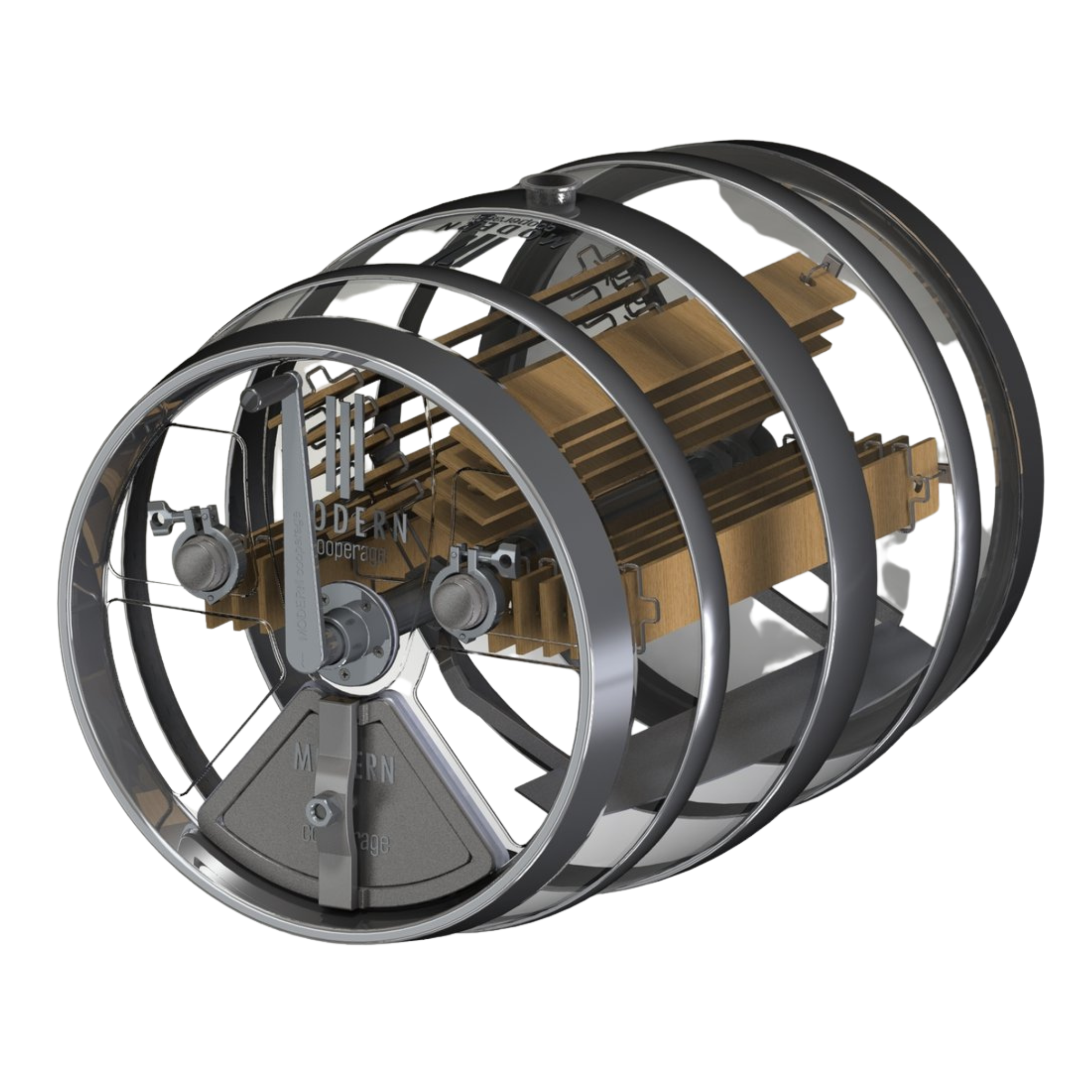

An entirely stainless steel construction and patented technologies allow winemakers to insert full-sized barrel staves, control the temperature, complete lees stirring in-place without opening the barrel, select oxygen permeability with variable membranes, and lose less wine to evaporation.

Over the last decade, the Modern Cooperage team has worked to perfect their innovative, modern barrel design. Jon Roleder, originally a manufacturing engineer, decided to apply his mechanical and material science background to making the future of cooperage. After a decade of research and iteration, the result is our fifth generation barrel.

The advantages of the Modern Cooperage barrel are myriad, but all stem from our essential belief that wine fermentation, maturation, and storage can be efficient and ecologically sound, while also improving the aesthetic impact that wood can have on a finished wine.

The Modern Cooperage Barrel

Quality winemaking made easier than ever before

- All food-safe stainless-steel construction with exterior dimensions matching traditional oak barrels.

- Barrel dimensions allow storage on existing racks for all-wood cooperage.

Stainless steel makes cleaning and storage considerably less labor-intensive. - Modern cooperage barrels can hold 31% more wine due to their significantly thinner exterior.

- Interior stave rack system can hold zero to 150% of the surface-to-volume ratio of a traditional oak barrel.

- Variably oxygen permeable membranes can consistently deliver oxygen transfer at a rate equivalent to all-wood cooperage, if desired.

- Affordably utilize new oak for every vintage and adjust oak extraction precisely to a desired specification with the number and type of staves used, with the potential to combine staves and toast levels from multiple cooperages.

We didn’t invent the barrel; we’ve made it better

- Make on-the-fly oak decisions during harvest with barrel-by-barrel modular stave selection.

- Separately managed oak extraction and oxygen transfer.

- Battonage for white wines without excessive oxygen introduction.

- Practical, easy-to-clean solution for red barrel fermentations.

- Smooth interior surface allows quick and complete sanitization of barrel surfaces.

- Less wood in total as well as all wood maintaining saturation with the wine leads to less possibility of microbial contamination.

Improved technologies provide significant economic benefits

- Reduce oak and physical barrel costs by up to 50% or more over the long term.

- Variable ways to take delivery, including buying or leasing.

- Reduced labor costs on new barrel preparation.

- Reduced labor costs from 24% fewer barrels to manage and maintain.

- Reduced labor costs from elimination of empty barrel maintenance.

- Reduced costs for water, waste water processing energy, freight, etc.

- Reduced warehouse costs with 24% less warehouse space required.

Constantly innovating for a greener & more sustainable future

- Up to 97.6% less oak harvested

- Reduce water required up to 90%

- Reduce waste water generation by up to 90% or more.

- Significantly reduce your shipping carbon footprint

Want to learn more?

Ready to take your winemaking to the next level? Get in touch with us and we’ll set up a time to meet.

- [email protected]

- (707) 304 - 5304